Material Specifications

| Property | Details |

| Material Composition | 100% Polyester (PET), various modifications available |

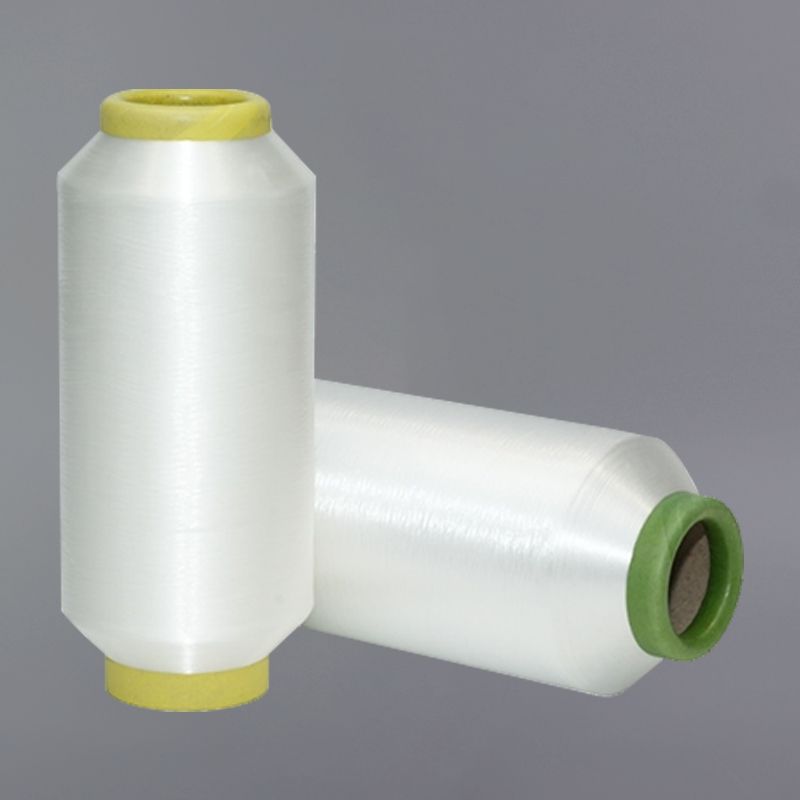

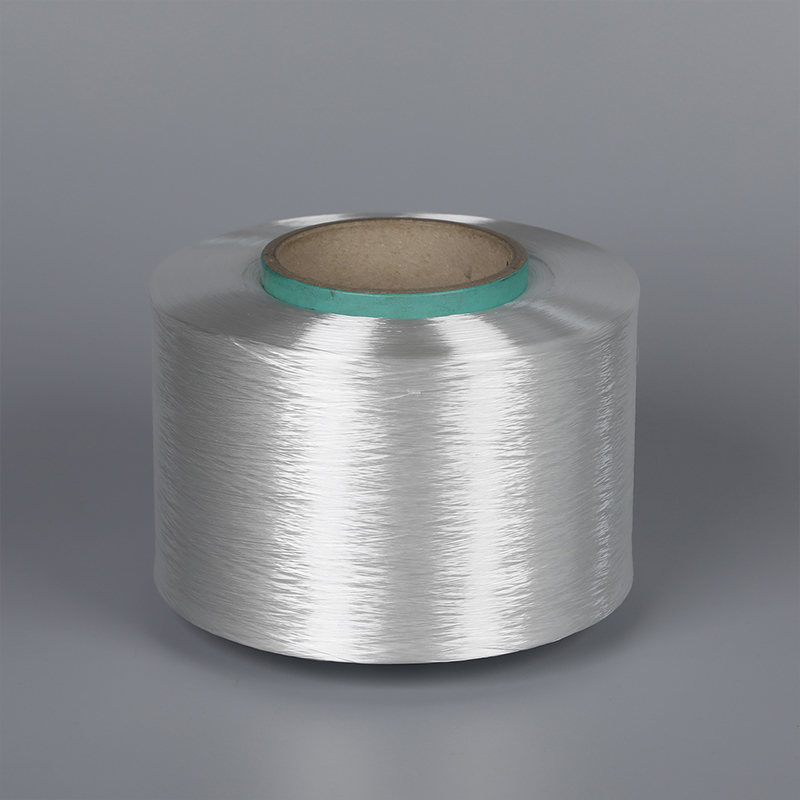

| Yarn Types | FDY (Fully Drawn Yarn), DTY (Draw Textured Yarn), POY (Partially Oriented Yarn for further processing) |

| Luster Options | Bright, Semi-Dull, Full-Dull, Matt finish |

| Filament Count | Standard and Microfilament options (e.g., 36F, 72F, 144F, 288F+) |

| Denier Range | Commonly 20D - 300D, custom ranges possible |

| Specific Treatments | Anti-UV, Anti-bacterial, Flame Retardant (upon request) |

Key Applications

Our specialty polyester yarns find their place in diverse markets requiring tailored material solutions:

- High-End Apparel: Fine denier for luxurious fabrics, DTY for comfortable stretch in activewear and fashion.

- Technical Textiles: Industrial sewing threads, webbing, and specialized filtration media demanding high strength and consistency.

- Automotive Interiors: Upholstery, headliners, and trim fabrics requiring durability, UV resistance, and aesthetic appeal.

- Home Furnishings: Curtains, upholstery, and bedding where both aesthetics and performance are key.

Core Advantages

Investing in specialty polyester yarns provides tangible benefits for your product line:

- Versatile Performance: Adaptable to various functional needs, from elasticity and softness to strength and resilience.

- Consistent Quality: Manufactured with strict quality controls to ensure uniform denier, strength, and dye uptake, reducing production waste.

- Customization Potential: Ability to modify yarn properties (e.g., cross-section, crimp, additives) to achieve specific desired outcomes for your end product.

- Cost-Effectiveness: Offers a superior performance-to-cost ratio compared to other high-performance fibers for many applications.

English

English 中文简体

中文简体