Material Specifications

| Property | Details |

| Material Base | 100% Low Melt Polyester or Sheath-Core (Standard PET Core / Low Melt Sheath) |

| Melting Point Options | Available ranges: 110°C, 160°C, 180°C (Customizable) |

| Yarn Count | 20D - 1000D+ available depending on structure |

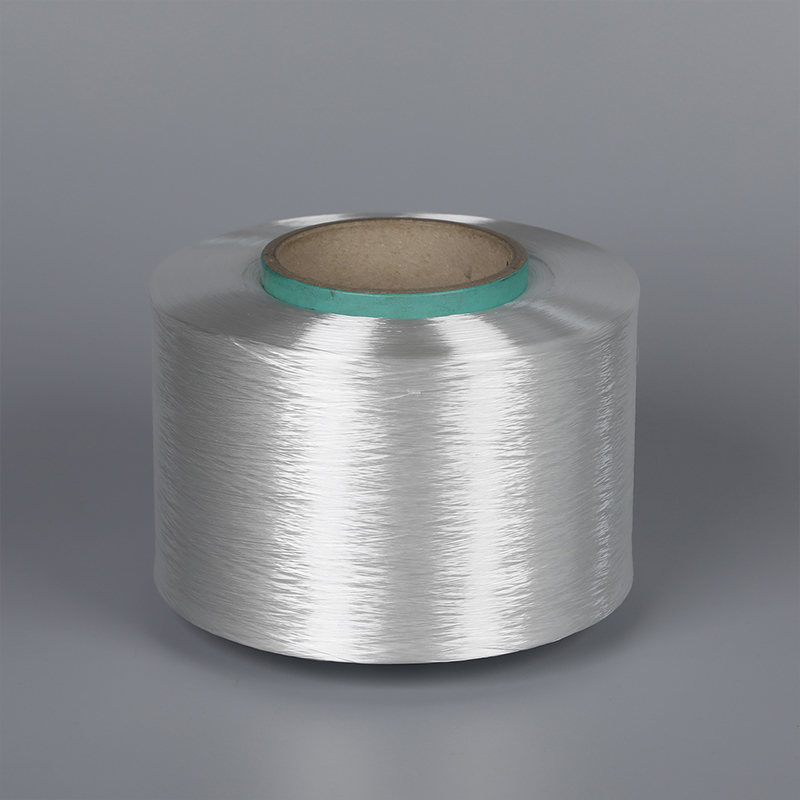

| Type | Filament (FDY) or Staple Fiber |

| Color | Raw White (Transparent after melting) or Dope Dyed Black |

Key Applications

Low melt technology is crucial in industries requiring precise bonding and structural integrity:

- Footwear Uppers: Used extensively in 3D fly-knitting to create structured, durable shoe uppers without external glue.

- Automotive Interiors: Bonding headliners, door panels, and trunk carpets, ensuring low VOC emissions.

- Technical Non-wovens: Filtration media and geotextiles where thermal bonding provides superior stability over chemical binders.

- Edge Sealing: Preventing fraying in woven or knitted fabrics.

Core Advantages

Integrating thermal bonding yarns offers significant process improvements:

- Eco-Friendly & Clean Process: Eliminates toxic solvents and volatile organic compounds (VOCs) associated with traditional glues. Cleaner factory environment.

- Superior Breathability: Unlike a solid film of glue, melted fiber bonding maintains the porous structure of the fabric, allowing air and moisture permeability.

- Precise Control: The bonding occurs only where the yarn is placed and heated, offering exact structural definition.

- Improved Recyclability: As the bond is same-material based (polyester bonding polyester), the final product is easier to recycle than glue-laminated materials.

English

English 中文简体

中文简体