Specification

| Raw Material Source | Post-consumer PET Bottles / Industrial Polyester Waste |

| Certification | GRS (Global Recycled Standard), OEKO-TEX Standard 100 |

| Recycling Method | Mechanical Recycling (Standard) / Chemical Recycling (Premium) |

| Tenacity Range | 3.2 cN/dtex to 4.8 cN/dtex (Comparable to Virgin PET) |

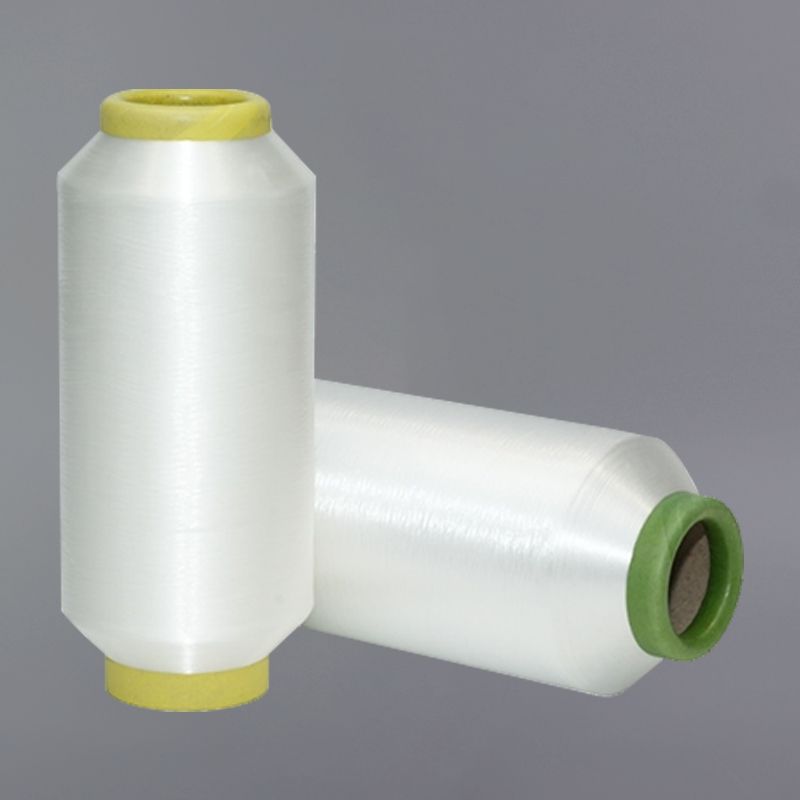

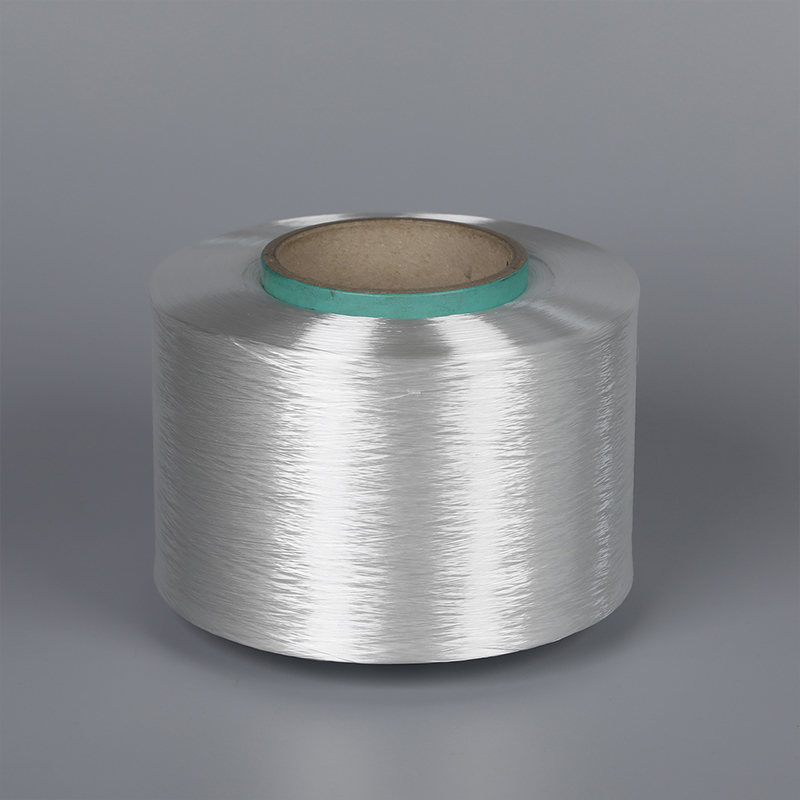

| Denier Range | 50D to 600D (POY, DTY, FDY) |

| Carbon Footprint Reduction | Estimated 30%−50% compared to Virgin Polyester |

| Dyeability | Excellent (Standard Disperse Dyes or Dope Dyed) |

| Moisture Regain | ∼0.4% (Same as Virgin PET) |

| Consistency | High purity chips ensure low filament break rates |

| Traceability | Transaction Certificate (TC) provided for every batch |

| Sustainability Impact | Reduces landfill waste and ocean-bound plastics |

Application

Recycled Polyester Yarn is utilized as a direct substitute for virgin polyester in any application where environmental sustainability is a key brand requirement.

Eco-Conscious Apparel and Activewear

The primary material for sustainable fashion collections, yoga wear, and outdoor fleeces. It offers the same moisture-wicking and durable properties as virgin polyester but with a marketing story that resonates deeply with modern consumers.

Corporate Gifting and Promotional Textiles

Used for sustainable bags, lanyards, and branded apparel. Companies use rPET to align their promotional activities with their internal CSR (Corporate Social Responsibility) targets.

Home Furnishings and Bedding

Woven into sustainable curtains, upholstery, and cushion fills. This allows home decor brands to offer "circular" products that appeal to the growing green building and interior design sectors.

Footwear Uppers and Linings

A key component in the shift towards "green" footwear. Major athletic brands use rPET for knit uppers and laces to reduce the overall environmental impact of their high-volume production models.

Advantage

Verifiable Sustainability (GRS Certified): Provides a fully traceable supply chain, allowing brands to make high-integrity environmental claims that are backed by third-party transaction certificates, effectively eliminating the risk of greenwashing.

Identical Performance to Virgin PET: Modern recycling technology ensures that rPET has the same strength, luster, and hand-feel as virgin polyester, meaning no changes are required to the client’s existing manufacturing machinery or processes.

Significant Reduction in Carbon Footprint: Using recycled chips saves energy and reduces petroleum extraction, allowing companies to meet their CO2 reduction targets and comply with emerging global environmental regulations.

Positive Consumer Perception: Products made from rPET command a premium in many markets and foster brand loyalty among the rapidly growing demographic of environmentally aware shoppers.

English

English 中文简体

中文简体