Specification

| Base Polymer | High Tenacity Polyester, Nylon 6/6 |

| Tenacity (Breaking Strength) | 6.5 cN/dtex to 9.5 cN/dtex |

| Elongation at Break | 8% to 20% (Low to Moderate) |

| Shrinkage (Boiling Water) | Low shrinkage (typically <3%) |

| UV Stability | Excellent (with stabilizers added) |

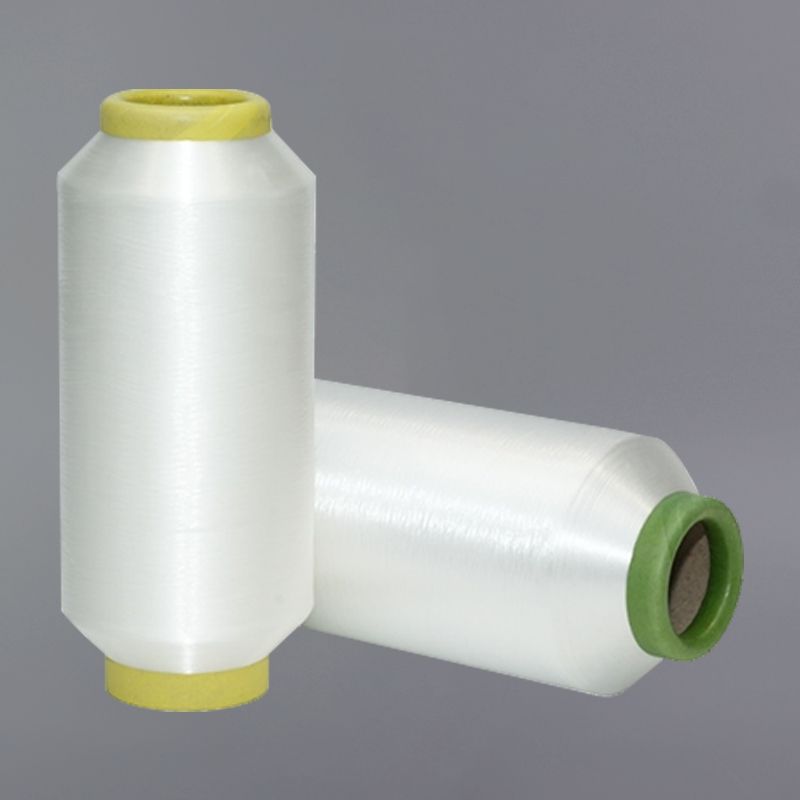

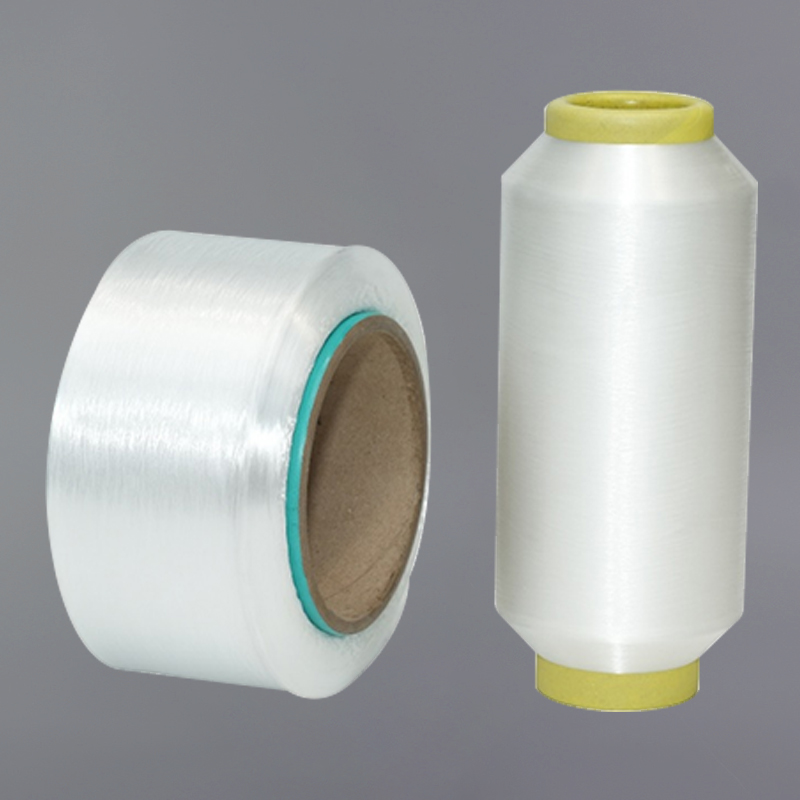

| Color | Raw White, Optical White, Black Dope Dyed |

| Denier Range | 210D - 6000D (Industrial Grade) |

Application

High Tenacity Yarn is the foundation for products demanding extreme strength and reliability.

Tire Cords and Mechanical Rubber Goods (MRG): Used as reinforcement in rubber products like tires, hoses, and conveyor belts, where it provides structural integrity against high pressures and friction.

Geotextiles and Construction: Essential in woven fabrics for soil stabilization, erosion control, and large-scale reinforcement in infrastructure projects.

Industrial Lifting & Rigging: Primary material for safety belts, heavy-duty industrial slings, cargo nets, and high-strength ropes due to its load-bearing capacity and shock resistance.

Automotive Safety: The core material for seatbelts and airbags, meeting critical regulatory safety standards.

Coated Fabrics: Used as the base fabric for banners, tarpaulins, and awnings that must withstand high winds and environmental stress. We offer customized twist levels to optimize performance for weaving or twisting operations.

Advantage

-

Unmatched Strength-to-Cost Ratio: Provides performance close to ultra-premium fibers but at a significantly more competitive price point, optimizing material costs for high-volume products.

-

Excellent Fatigue Resistance: Designed to withstand repeated cycles of loading and unloading, crucial for dynamic applications like safety restraints and conveyor belts.

-

Dimensional Stability: Low shrinkage and consistent denier ensure that the final textile product maintains its shape and tension over time and temperature fluctuations.

-

Superior Abrasion Resistance: The tight molecular structure lends itself to excellent surface hardness, making it highly durable against friction and mechanical wear.

-

Chemical Versatility: High Tenacity Polyester offers good resistance to UV light and most chemicals, making it suitable for exposed outdoor and industrial settings.

English

English 中文简体

中文简体