Specification

| Conductive Component | Carbon or Metallic Compounds |

| Surface Resistivity | 106 to 109 Ω/sq (IEC 61340-4-1) |

| Charge Decay Time | <0.5 seconds (FTMS 101C, Method 4046) |

| Base Polymer | Polyester, Nylon, Polypropylene |

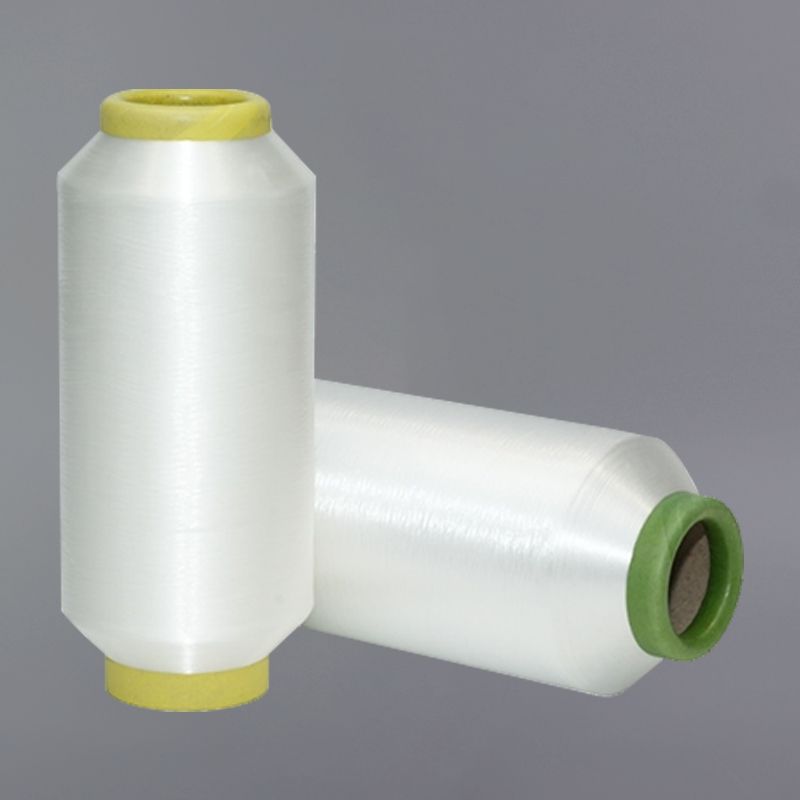

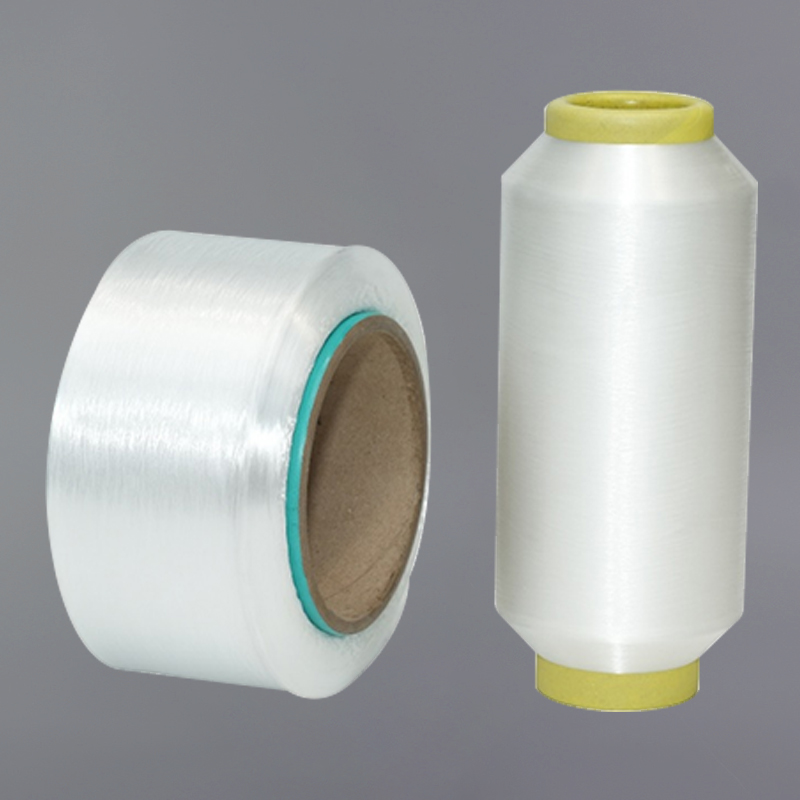

| Color | Grey, Black, or transparent carrier fiber |

| Denier Range | 30D - 150D |

| Durability | Permanent (withstanding >100 wash cycles) |

Application

The primary application of Anti-Static Yarn is in areas requiring Electrostatic Discharge (ESD) protection and contamination control.

Electronics and Semiconductors: Essential for manufacturing cleanroom garments, gloves, and workstation mats to prevent damage to microchips and sensitive components.

Petroleum and Chemical Industry: Used in protective workwear, tank linings, and conveyor belts to eliminate sparks that could ignite flammable vapors or dust.

Medical Operating Rooms: Ensures the safety of patients and equipment by preventing static buildup that can interfere with sensitive monitoring devices.

Technical Filtration: Utilized in air filters where dust buildup can be exacerbated by static cling, improving filter efficiency and longevity.

High-Speed Processing: Integrated into production machinery fabrics (e.g., paper and printing) to prevent materials from sticking or bunching due to static.

Advantage

-

Permanent Protection: The conductive element is embedded within the fiber, guaranteeing anti-static properties that last the entire lifetime of the textile, unlike topical chemical sprays.

-

Safety Compliance: Meets stringent international standards for ESD control (e.g., EN 1149), providing verifiable safety for hazardous work environments.

-

Comfort and Breathability: The conductive elements are fine and integrate seamlessly, ensuring the final fabric remains soft, lightweight, and comfortable for extended wear.

-

Superior Cleanroom Performance: Reduces the risk of particle attraction due to static cling, critical for ISO Class cleanroom environments where air cleanliness is paramount.

-

Versatile Integration: Compatible with various yarn counts and base polymers (Nylon, Polyester), allowing seamless integration into diverse fabric constructions (woven, knit, non-woven).

English

English 中文简体

中文简体