Specification

| Polymer Base | Polyvinyl Alcohol (PVA) |

| Dissolving Temp. | 20∘C, 40∘C, 70∘C, or 90∘C (Customizable) |

| Dissolving Time | 1 to 5 minutes (depending on temp and agitation) |

| Tenacity | 3.5 to 5.0 cN/dtex |

| Moisture Regain | High (5%−9%) |

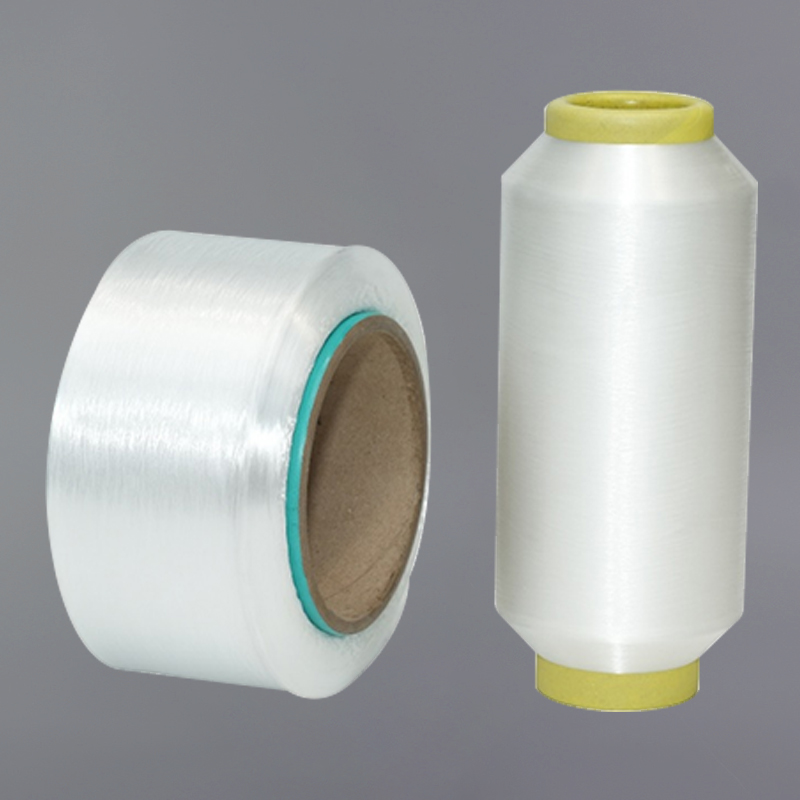

| Denier Range | 20D to 200D |

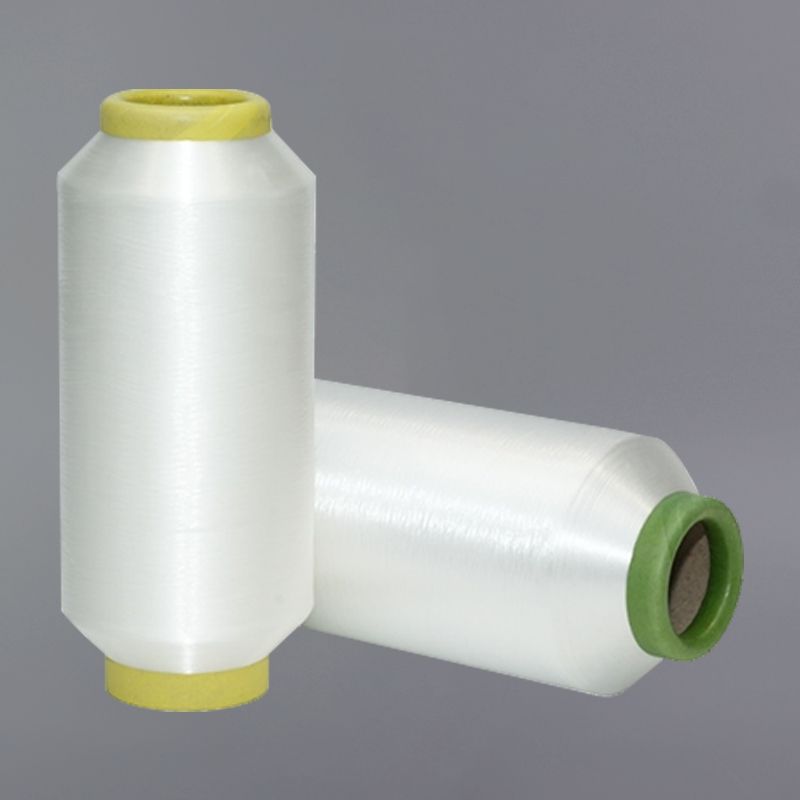

| Color | Natural White (Typically undyed) |

| Biodegradability | Biodegradable in wastewater treatment systems |

| Safety | Non-toxic, eco-friendly decomposition |

| Storage | Must be kept in humidity-controlled packaging |

Application

Water-Soluble Yarn is the "secret ingredient" in luxury garment construction and high-efficiency industrial knitting.

Luxury "Zero-Twist" Towels and Linens

Used as a carrier yarn to weave untwisted cotton fibers. Once the towel is washed, the PVA disappears, leaving a towel that is 30% more absorbent and much softer than standard towels.

Guipure and Chemical Lace

The embroidery is stitched onto a PVA fabric base. After washing, the base dissolves, leaving only the intricate lace pattern. This allows for complex, "floating" designs that cannot be made with traditional backing.

Separation of Knitted Components

Used between knitted collars, cuffs, or sweater panels. Instead of cutting them apart manually, the factory washes the batch, and the PVA "separation row" dissolves, cleanly detaching the pieces without damaging the edges.

Hospital Laundry Bags

PVA yarn is used to stitch laundry bags for contaminated hospital linens. The entire bag is placed in the washing machine; the thread dissolves, releasing the clothes into the wash without staff ever having to touch the biohazardous materials.

Advantage

Precision Disappearance: Dissolves completely at the exact temperature specified, ensuring no sticky residue or "stiffening" of the final textile product.

Enables "Impossible" Fabrics: Allows for the creation of ultra-light, hollow, or open-work structures that have no structural strength during the weaving process but are stable once finished.

Labor-Saving Automation: Eliminates the need for manual cutting or "picking" of support threads, drastically reducing labor costs and increasing throughput for lace and knitwear factories.

Environmental Safety: PVA breaks down into water and CO2 in biological wastewater treatment plants, making it a sustainable choice compared to solvent-based removal methods.

English

English 中文简体

中文简体