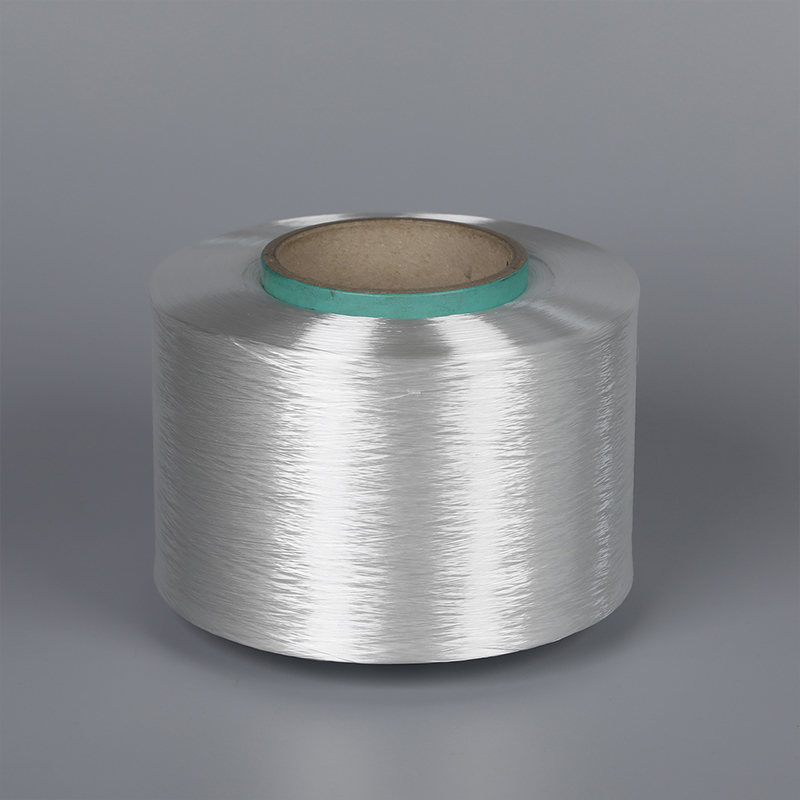

Specification

| Denier Range | 20D - 300D |

| Base Polymer | Co-PET, Co-PA (customizable) |

| Melting Point | 85∘C to 180∘C (±3∘C) |

| Color | Raw White, Semi-Dull, Black |

| Tenacity | 1.5 cN/dtex - 4.5 cN/dtex |

| Filament Count | F12 to F96 (Customized) |

| Package Type | Paper Bobbin (Conical or Cylindrical) |

Application

The self-adhesive nature of Low Melting Yarn makes it essential across various industries where strong, clean bonding is required.

Footwear Components: LMY is extensively used to reinforce shoe uppers, toe puffs, and heel counters, providing structural integrity without stiffeners.

Filter Media: In non-woven filtration fabrics, LMY serves as the binder to hold staple fibers together, creating porous and highly effective filter structures for air and liquid purification.

Automotive Interiors: Used in lamination for headliners, trim, and sound insulation panels for cleaner assembly and lighter weight.

Apparel Interlinings: Creates seamless seams and reinforcement in high-end sportswear, innerwear, and technical garments, replacing traditional fusible interlinings.

Composite Materials: Utilized in fiberglass and carbon fiber prepregs as a binder, enabling cleaner composite production.

Advantage

-

Environmental Efficiency: Eliminates the need for solvent-based or aqueous chemical adhesives, reducing VOC emissions and streamlining the production process.

-

Superior Bond Strength: Achieves a consistent, strong, and permanent thermal bond across the entire structure, enhancing product durability and stability.

-

Process Simplification: Allows manufacturers to integrate the bonding step directly into weaving, knitting, or non-woven production, significantly reducing labor and time.

-

Excellent Softness and Drape: Unlike chemical adhesives, LMY retains the natural softness and flexibility of the textile, crucial for comfortable apparel and flexible composites.

-

Wide Processing Range: Our Co-PET and Co-PA variants cover a broad range of melting temperatures, making them compatible with almost any existing fiber blend or machine setup.

English

English 中文简体

中文简体